Quality & Accreditation

At Leebex Metals, quality is the essence of the entire production process. Leebex Metals has a team of professional, skilled and qualified engineers and technologists with immense industry experience. The skilled and qualified manpower, analyse and verify everything that enters the production process multiple times and the finished products are later packaged in full sized wooden boxes, poly material and pallets.

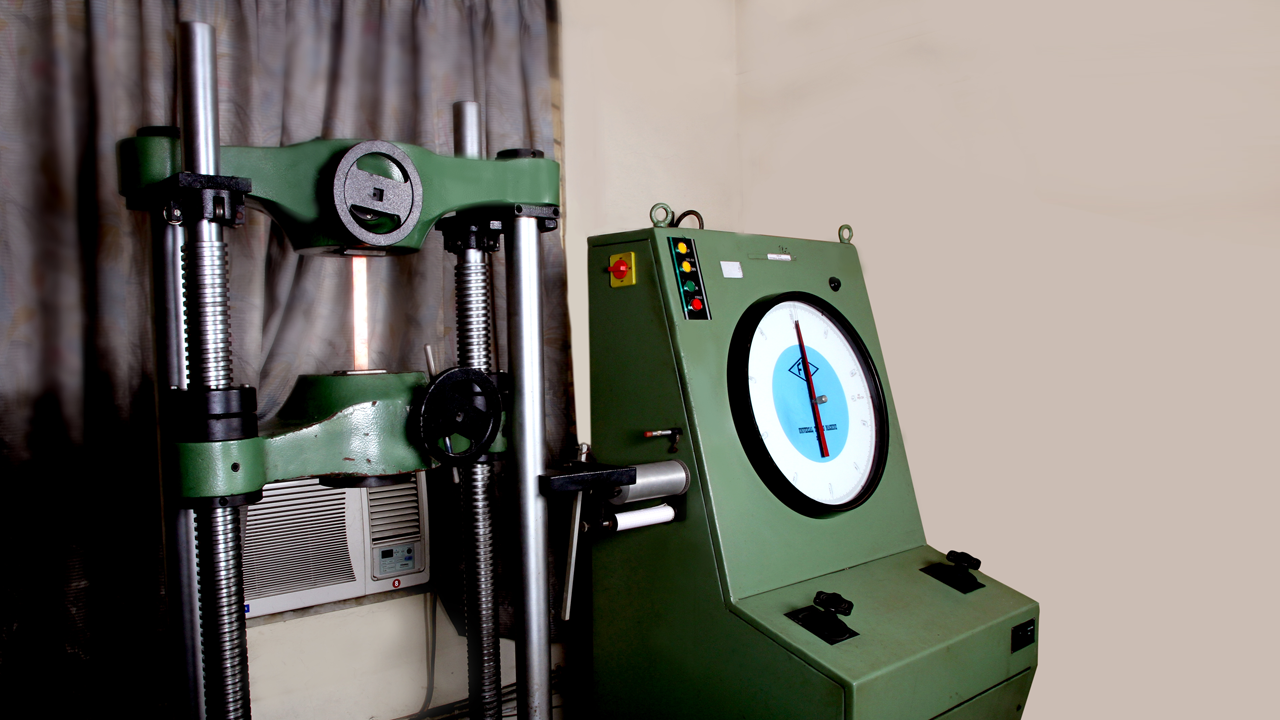

Every raw material input is defined and tested in NABL certified laboratory to ensure its superior quality. The parent companies Leebo Metals and Excel Metal Engineering, for a long time, are being recognised for their adherence to industry standards and have acquired an ISO 9001- 2015 Certification.

Leebo Metals has also been previously awarded with Star Export House certification and is also TUV Rheinland certified. Excel Metal Engineering has all the quality machinery installed for best results based on service and quality. Leebex Metals has set up a benchmark for the products, and the company’s main focus is to maintain industry standards in accordance with their parent companies.

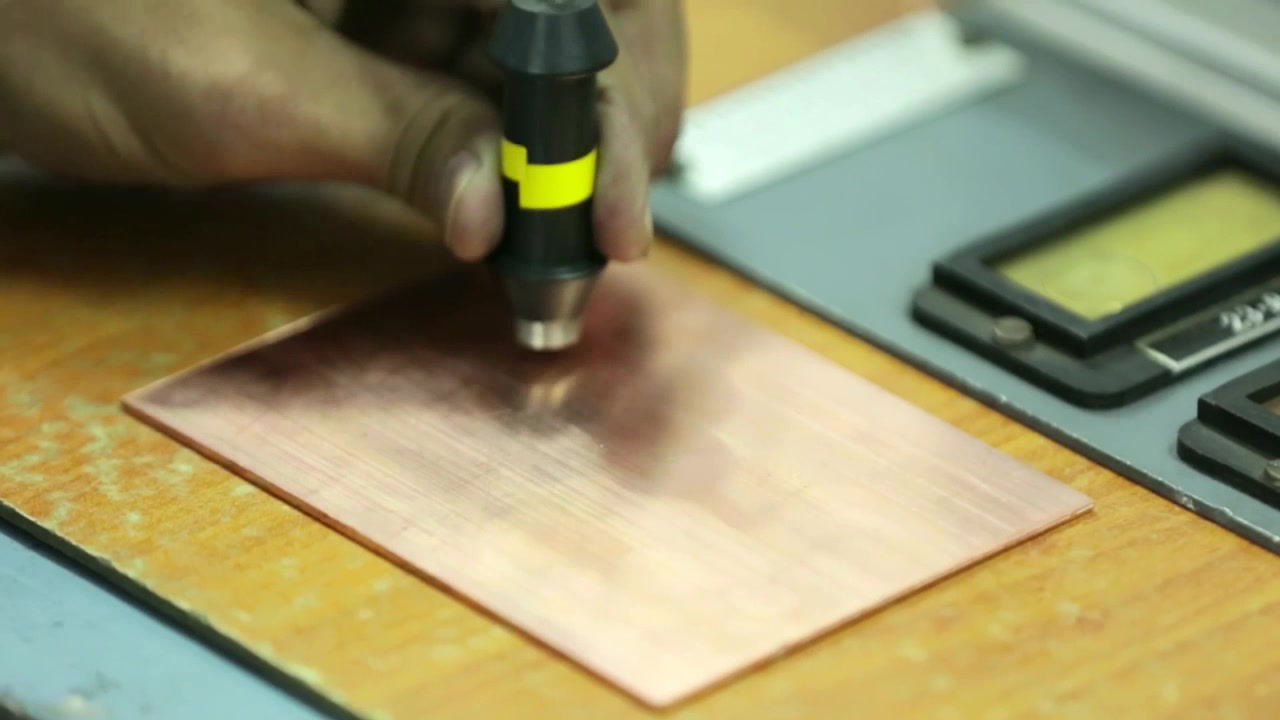

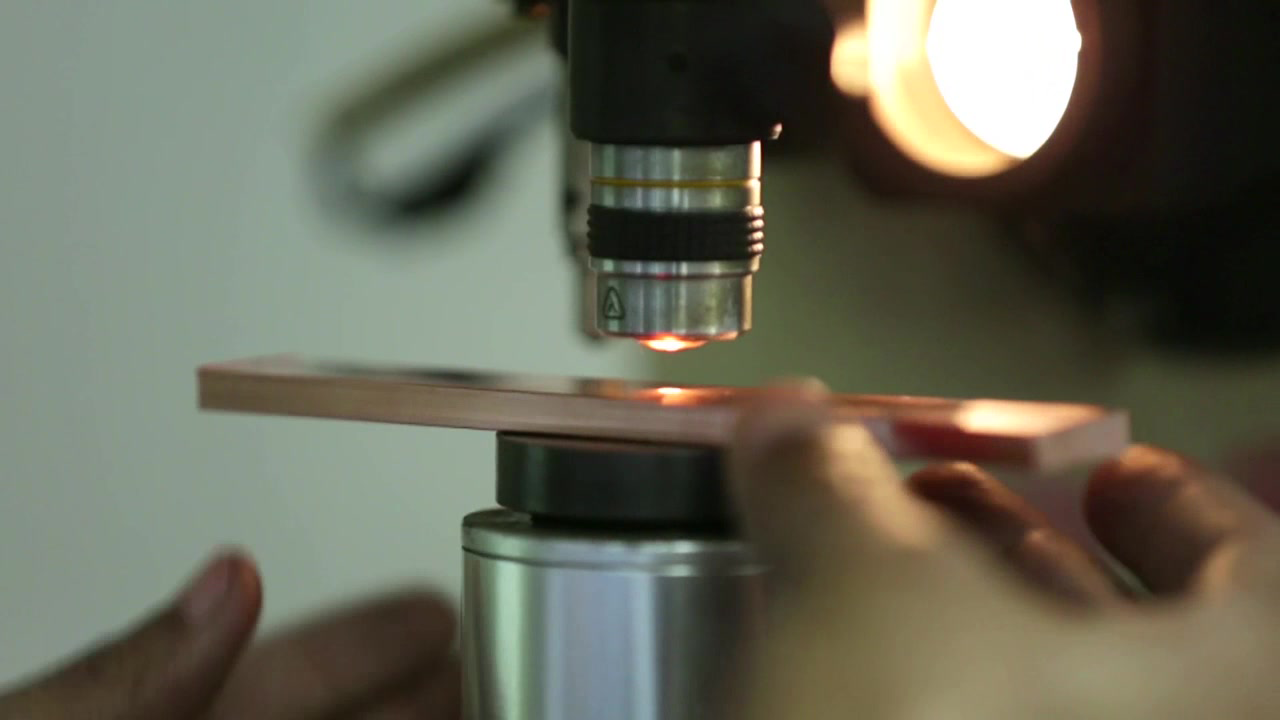

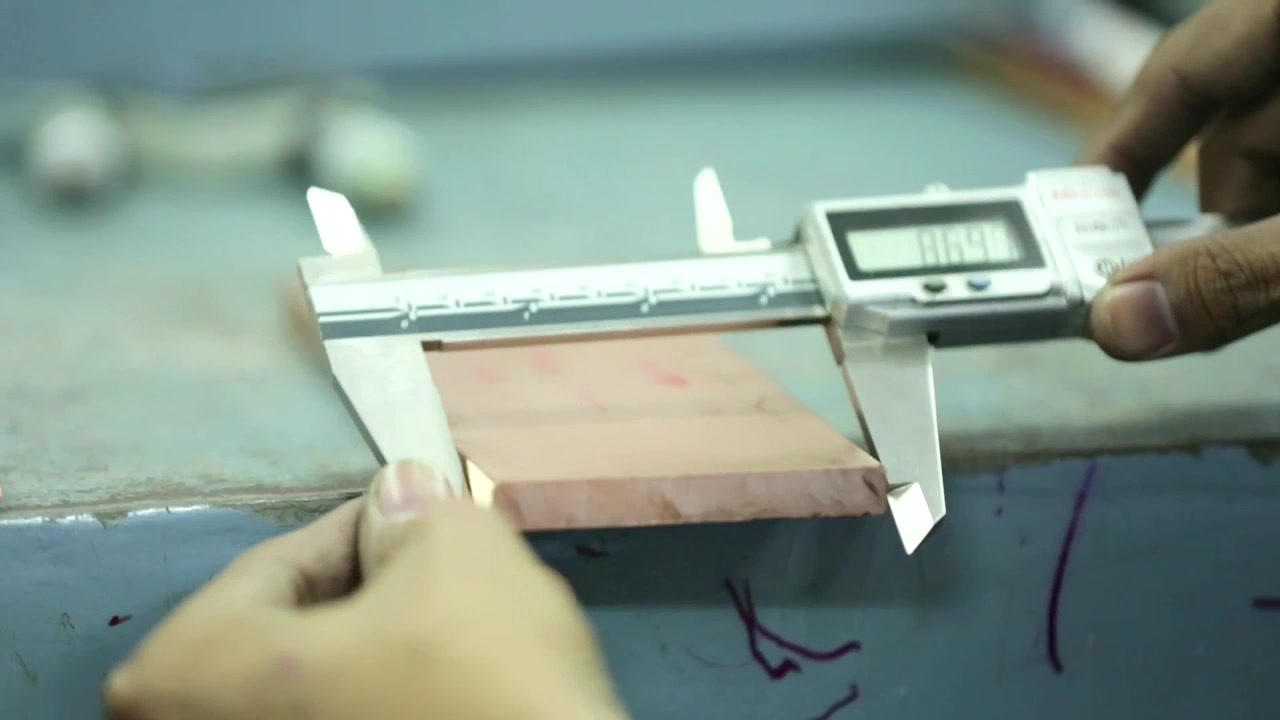

Leebex Metals uses LME Grade A Copper Cathodes which are tested and certified. Each stage of the manufacturing process has a stringent quality testing procedure to ensure that there’s no degradation in the precision of the products.

The final products then undergo multiple testing procedures in Leebex Metals’s in-house laboratory which then provides a test certificate upon successful approval of the materials. Our entire manufacturing process is carefully taken care of, and the products are dispatched only after the final QC is done. Leebex Metals takes care of everything until it reaches the customers.